The Hydrostatic Transmission Pump - Explained

HST

Hydraulic transmissions allow tractors/harvester to convert mechanical energy into hydraulic energy and then back to mechanical energy. This allows for smooth forward and reverse speed fluctuations and a smaller gear unit without sacrificing performance. Let's take a look at the science behind what makes a hydrostatic transmission work.The Principles Behind Hydropower:

- Liquids cannot be compressed

- Liquids have no shape

- Liquids transmit pressure in all directions and have equal force to all perpendicular surfaces

Advantages of HST

- Ease of use. There are no levers to shift gears or clutches to pedal. All you have to do is move one control lever.

- Infinitely variable. The forward speed variation can be changed from 0 to full.

- compact size. The gearbox is much smaller because it does not rely on the

- Gearset to increase torque or change direction.

- The hydraulic transmission delivers torque smoothly and efficiently.

To understand how hydrostatic pressure transfer works, we first need to understand the basic properties of fluids. All vertical planes

- The speed of your transmission’s output is dependent on the rate of volume the oil is flowing. This is measured in gallons per minute (GPM).

- The direction of your transmission’s output is dependent on which direction the oil is being pumped.

- The power of your transmission’s output is dependent on the oil’s pressure.

- The advantages of hydraulic transmissions are:

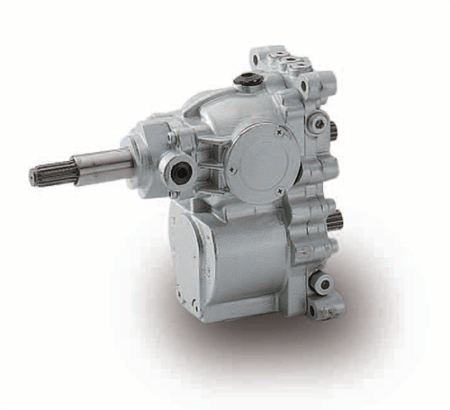

Parts of HST

- Ease of use. There are no levers to shift gears or clutches to pedal. All you have to do is move one control lever.

- Infinitely variable. The forward speed variation can be changed from 0 to full.

- compact size. The gearbox is much smaller because it does not rely on the gearset to increase torque or change direction. The

hydraulic - hydraulic transmission delivers torque smoothly and efficiently.

Working

The oil begins in the reservoir, which is the rear differential case of the Kabucadet Garden Tractor. When the engine is running, it rotates the drive shaft. The drive shaft is connected to the input shaft that rotates both the charge pump and the axial piston pump. The charge pump pumps oil into the transmission case through an oil filter. Oil flows into the housing and closed circuit oil passages.

When the operator moves the transmission control lever, the angle of the swash plate changes and the piston moves in and out of the piston cylinder as the piston rotates. The reciprocating motion of the piston causes oil to circulate through the oil passage to the axial piston motor. Since the motor is set at a fixed angle, the piston rotates the motor and pushes the oil back into the pump. The engine is connected to the output shaft, which rotates a large differential gear and transfers power to the rear wheels.

When the operator moves the transmission control lever, the angle of the swash plate changes and the piston moves in and out of the piston cylinder as the piston rotates. The reciprocating motion of the piston causes oil to circulate through the oil passage to the axial piston motor. Since the motor is set at a fixed angle, the piston rotates the motor and pushes the oil back into the pump. The engine is connected to the output shaft, which rotates a large differential gear and transfers power to the rear wheels.